Fats and Oils Consultancy

Our team of food technologists focuses on our client’s perspective and walk together in shaping up their food product ideas, food product formulation, stability studies, food testing, nutritional testing, quality, and shelf-life testing.

FATS & OIL

This section focuses on the processing of fats & oil products unless otherwise noted.In general, the processing technology described for one type of oil can be successfully applied to other oil seeds.

Nutritional information

The sources of fats and oils include edible vegetable oils, palm oils, industrial oils, animal fats, and marine oils. Fats and oils provide more calories per gram than any other food, but they contain no protein and few micronutrients. The predominant substances in fats and oils are triglycerides, chemical compounds containing any three fatty acids combined with glycerol.Fats with a high percentage of saturated fatty acids, e.g., butter and lard, tend to be solid at room temperature. Those with a high percentage of unsaturated fatty acids are usually liquid oils, e.g., sunflower, safflower, and corn oils.

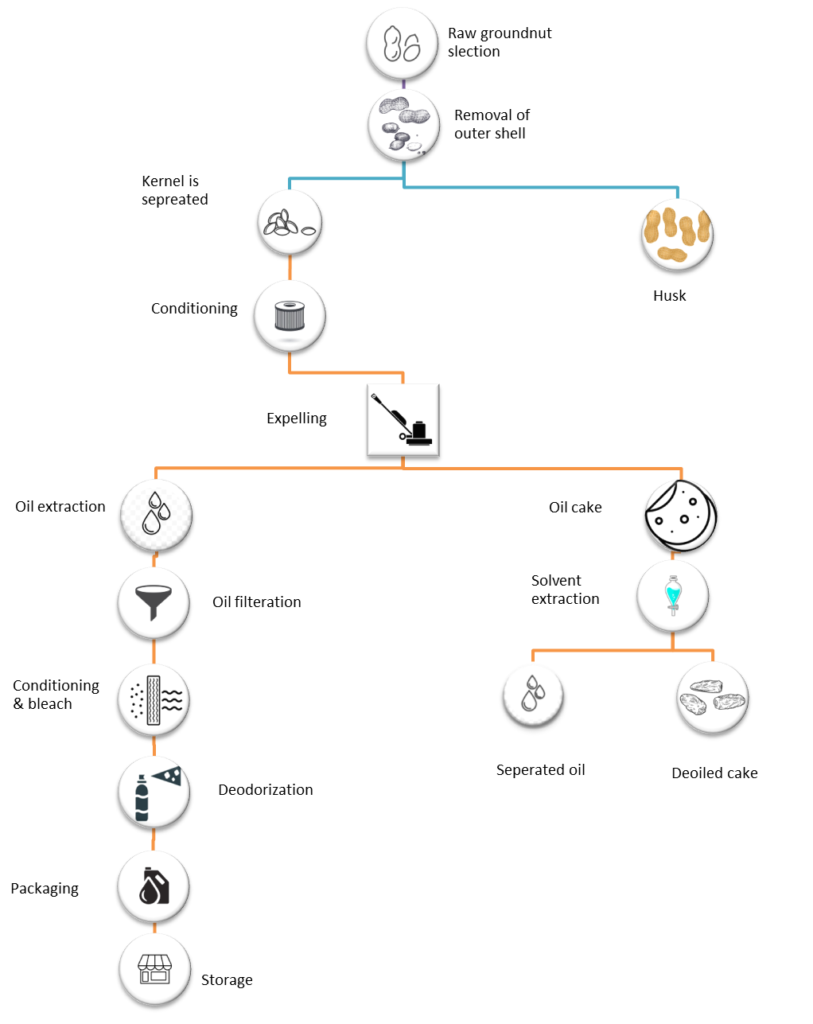

Reference Flow Chart For Groundnut Oil

Quality concern

The process of hydrogenation is used by the food industry to convert unsaturated oils to saturated solid fats, which are more resistant to rancidity. However, hydrogenation also causes the formation of transfatty acids. The main aspects of this functionality choice are

(a) melting point and melting profile (how the solid fat content changes with temperature),

(b) crystallization characteristics,

(c) storage stability (particularly oxidative stability) and

(d) nutritional characteristics

Type of products

- Interesterified vegetable fat/oil/ sardine oil

- Partially hydrogenated oil

- Beef fat/mutton fat/goat fat/lard/cocoa butter/refined salseed fat/kokum fat

- Mango kernel fat/dhupa fat/ phulwara fat/ shea butter/borneo tallow/ illipe butter

- Peanut butter

- Margarine and fat spreads

- Vanaspati/bakery shortening

FAQ's

Food fortification or enrichment is the process of adding micronutrients (essential trace elements and vitamins) to food. .Food fortification is a proven, sustainable, cost-effective and high-impact solution to address micronutrient deficiencies.

Food fortification can also be categorized according to the stage of addition:

1. Commercial and industrial fortification (Finished products)

2. Bio fortification (breeding crops to increase their nutritional value, which can include both conventional selective breeding, and genetic engineering)

3. Home fortification (example: vitamin D drops)

Fortification compounds used

• Vitamin A

• Vitamin D

Preservatives are added to food to fight spoilage caused by bacteria, molds, fungus, and yeast. Preservatives can keep food fresher for longer periods of time, extending its shelf life. Food preservatives also are used to slow or prevent changes in color, flavor or texture and delay rancidity.

When it comes to preserving foods, there are two methods: physical and chemical. Drying, refrigerating and freezing are examples of physical preservation. Chemical preservation involves adding ingredients called additives to food in order to prevent oxidation, rancidity, bacterial growth, etc. There are both natural and synthetic preservatives that are used in food

Common preservatives used

• Nisin

• Sorbic acid

• Propionic acid

Antioxidants are used as food additives to help guard against food deterioration. Exposure to oxygen and sunlight are the two main factors in the oxidation of food. Antioxidants are an especially important class of preservatives as, unlike bacterial or fungal spoilage, oxidation reactions still occur relatively rapidly in frozen or refrigerated food.

These preservatives include natural & synthetic antioxidants

Common antioxidants used

• L- Ascorbic acid (Natural)

• Ascorbyl palimtate ( Synthetic)

• Tocopherols (Natural)

• Propyl gallate (Synthetic)

• Butylated hydroxy anisole ( Synthetic)

Acidity regulators, or pH control agents, are food additives used to change or maintain pH (acidity or basicity).Theycan be organic or mineral acids, bases, neutralizing agents, or buffering agents.

Some acidifiers also act as stabilizers; others help antioxidants or emulsifiers, or assist in colour retention. It may seem a minor parameter, but to maintain the appropriate pH is the first step to ensure food safety and a longer shelf life.

Commonly used acidity regulators

• Calcium and magnesium carbonates

• Sodium bicarbonate and Sodium carbonate

• Sodium and Calcium hydroxide

• Sodium phosphate

The colour of your food plays an important role by visually stimulating your appetite. But have you ever wondered where these colours come from?

Food colourings are of two types: artificial and natural. Not surprisingly, natural colours are a better alternative as they are wholly derived from plants. Natural colouring usually appears less vibrant when compared to artificial colouring. This however, does not affect the taste of your food.

Commonly used food colours

• Natural -Chlorophyll

• Natural -Caramel

• Natural -Curcumin or turmeric

• Natural – Beta carotene

• Natural -Riboflavin, Lactoflavin

• Natural -Annato

• Natural -Saffron

• Natural -Canthaxanthin

• Synthetic- Ponceau 4R

• Synthetic- Carmoisine

• Synthetic- Erythrosine

• Synthetic- Tartrazine

• Synthetic- Sunset Yellow FCF

• Synthetic- Indigo carmine

• Synthetic- Brilliant blue FCF

• Synthetic- Fast green FCF

Acidity regulators, or pH control agents, are food additives used to change or maintain pH (acidity or basicity).Theycan be organic or mineral acids, bases, neutralizing agents, or buffering agents.

Acidity regulators, or pH control agents, are food additives used to change or maintain pH (acidity or basicity).Theycan be organic or mineral acids, bases, neutralizing agents, or buffering agents.

Commonly used acidity regulators

• Calcium and magnesium carbonates

• Sodium bicarbonate and Sodium carbonate

• Sodium and Calcium hydroxide

• Sodium phosphate